LESLIE 147

My Odyssey Trying To Get A Vintage Jensen V21 In Good Working Condition

Since the fitted, overly bright horn driver didn't satisfy me, I was going to get an original Jensen V21 for that classic Leslie sound. Apart from having a smoother roll-off at the high end, a V21 really blends with the woofer, resulting in a coherent sound over the whole frequency range. The other driver rather gave an impression of two separate parts of the sound (LF and HF), with a hole in the middle.

After removing the driver, detaching the spindle plate (which receives the horn bearing) and the "flower pot" style encapsulation, the driver itself showed no manufacturer codes or serial numbers. An inquiry at Hammond/USA yielded that it's an OEM version of the PD-60 by Atlas, which they made exclusively for Hammond, to be fitted in 122a/xb/3300 Leslies made in the 2000's.

My Odyssey Trying To Get A Vintage Jensen V21 In Good Working Condition

Since the fitted, overly bright horn driver didn't satisfy me, I was going to get an original Jensen V21 for that classic Leslie sound. Apart from having a smoother roll-off at the high end, a V21 really blends with the woofer, resulting in a coherent sound over the whole frequency range. The other driver rather gave an impression of two separate parts of the sound (LF and HF), with a hole in the middle.

After removing the driver, detaching the spindle plate (which receives the horn bearing) and the "flower pot" style encapsulation, the driver itself showed no manufacturer codes or serial numbers. An inquiry at Hammond/USA yielded that it's an OEM version of the PD-60 by Atlas, which they made exclusively for Hammond, to be fitted in 122a/xb/3300 Leslies made in the 2000's.

Being out of production since decades, Jensen V21 are mostly available second-hand from the USA, they hardly ever show up in Europe. I got one off a reputable seller from the US. However, after installing and testing it in my 147, it abruptly went into buzzing when I played a few specific notes, while other, neighbouring notes played just fine - and that at just moderate levels. Not normal! To find out what was wrong, I dissected the driver...

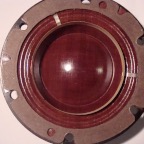

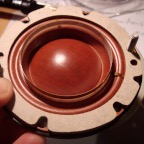

Removing the outer mounting plate reveals the plastic top plate inside, which holds the diaphragm in place underneath and also acts as a waveguide for the sound, improving linearity. Interestingly, all V21 top plates I've seen have the tip cut off, with some cork pasted inside - obviously a modification made by the Leslie people themselves, which probably has to do with another mod we shall see further down.

I detached top plate and diaphragm to have access to the magnet and its gap (where the voice coil normally resides). Using adhesive tape, I gave it a good clean, slowly going along both the inner and outer edge of the gap. That way, any particles that somehow made their way into the gap, causing rattles or rubbing of the voice coil, would stick to the tape. Nothing major turned up, though.

Aligning the diaphragm

My second guess was that the diaphragm might just have been misaligned. The alignment procedure I did as follows: I put the waveguide back on, put the screws in place without quite tightening them, hooked the electric terminals up to the cable coming from the Leslie crossover and applied signal. Going over the keyboard range chromatically with just the 8' drawbar out, I found one of the notes that buzzed the most, and while holding it (as e.g. by sticking something into the gap between neighbouring keys), I moved the phase plug around until the buzzing got minimal. Normally, repeating that a couple of times with different notes, I should have been able to find a position with overall minimum distortion from the driver - but with this one, it didn't seem to be possible.

I detached top plate and diaphragm to have access to the magnet and its gap (where the voice coil normally resides). Using adhesive tape, I gave it a good clean, slowly going along both the inner and outer edge of the gap. That way, any particles that somehow made their way into the gap, causing rattles or rubbing of the voice coil, would stick to the tape. Nothing major turned up, though.

Aligning the diaphragm

My second guess was that the diaphragm might just have been misaligned. The alignment procedure I did as follows: I put the waveguide back on, put the screws in place without quite tightening them, hooked the electric terminals up to the cable coming from the Leslie crossover and applied signal. Going over the keyboard range chromatically with just the 8' drawbar out, I found one of the notes that buzzed the most, and while holding it (as e.g. by sticking something into the gap between neighbouring keys), I moved the phase plug around until the buzzing got minimal. Normally, repeating that a couple of times with different notes, I should have been able to find a position with overall minimum distortion from the driver - but with this one, it didn't seem to be possible.

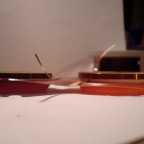

I took everything apart again, and - examining the diaphragm more closely, found that the former of the voice coil was actually tilted! No wonder I was getting these strange buzzes, since the voice coil was no longer moving uniform within the gap. To my surprise, the seller told me that the driver had even been tested in a leslie - which actually should have revealed the problem. Usually, these things only tend to go unnoticed when people just run a sweep with a function generator, most of which have too low an output to deliver appropriate power.

So Leslie actually modded their V21's...?

While I was at it anyway, I was going to dissect the driver completely, to see if there was anything else wrong. Removed the gaskets, desoldered the leads from the terminals, and removed the diaphragm - which revealed another "custom" modification: There's a hole cut into the dome (which, by it's coarse shape, denotes that it's not exactly stock), with cotton-wool like material inside the cavity, functioning as a pourous absorber. It seems that they wanted to attenuate the V21's high end (which is not exactly overwhelming in the first place). If the cork inserted at the other end of the cavity is there for acoustic reasons, I cannot say (maybe to counteract cavity resonance, with cork being more rigid and less pourous than the wool, but less rigid and more pourous than the plastic). In any case, a Hammond techs tell me that this arrangement is to be found in virtually all V21's. Thus, it seems that it was a mod by Leslies themselves, done in the factory to every single V21, rather rather asking Jensen for a revised design...?

A funny thing was to find some remains inside that looked to be a deceased insect (marked with the plier's tip on the picture)! But I highly doubt that the coil former was tilted because of that - usually, overheating of the voice coil is the reason, due to running it at full power for a long time.

So Leslie actually modded their V21's...?

While I was at it anyway, I was going to dissect the driver completely, to see if there was anything else wrong. Removed the gaskets, desoldered the leads from the terminals, and removed the diaphragm - which revealed another "custom" modification: There's a hole cut into the dome (which, by it's coarse shape, denotes that it's not exactly stock), with cotton-wool like material inside the cavity, functioning as a pourous absorber. It seems that they wanted to attenuate the V21's high end (which is not exactly overwhelming in the first place). If the cork inserted at the other end of the cavity is there for acoustic reasons, I cannot say (maybe to counteract cavity resonance, with cork being more rigid and less pourous than the wool, but less rigid and more pourous than the plastic). In any case, a Hammond techs tell me that this arrangement is to be found in virtually all V21's. Thus, it seems that it was a mod by Leslies themselves, done in the factory to every single V21, rather rather asking Jensen for a revised design...?

A funny thing was to find some remains inside that looked to be a deceased insect (marked with the plier's tip on the picture)! But I highly doubt that the coil former was tilted because of that - usually, overheating of the voice coil is the reason, due to running it at full power for a long time.

I purchased a second V21 from the US - however, it wasn't as clean as the first one, the adhesive padding ring of the top plate was desintegrating. But much worse, soon I found out that the diaphragm of this driver had a voice coil even more tilted than the first one! How annoying.

I had heard that you can re-form diaphragms when carefully applying some heat. Since I had nothing to lose, I took a fan at it's lowest temperature setting and tried to distribute the heat over the whole diaphragm as evenly as possible. Afterwards, the coil former was no longer tilted off-axis - but instead, it wasn't exactly circular anymore, so now it wouldn't fit into the magnet's gap... bad luck.

Installing a replacement diaphragm...

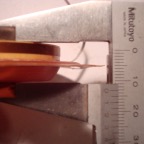

In the meantime, the seller of the first V21 had sent me a new diaphragm. Before replacing the old one, though, I had to deal with some more of those lousy details. Placed side by side, you can see that the new diaphragm has all of it's holes in the wrong position. That was the easier part: I carefully marked the spaces for new holes, got a hole puch (a nice tool to have for occations like this) and went ahead.

I had heard that you can re-form diaphragms when carefully applying some heat. Since I had nothing to lose, I took a fan at it's lowest temperature setting and tried to distribute the heat over the whole diaphragm as evenly as possible. Afterwards, the coil former was no longer tilted off-axis - but instead, it wasn't exactly circular anymore, so now it wouldn't fit into the magnet's gap... bad luck.

Installing a replacement diaphragm...

In the meantime, the seller of the first V21 had sent me a new diaphragm. Before replacing the old one, though, I had to deal with some more of those lousy details. Placed side by side, you can see that the new diaphragm has all of it's holes in the wrong position. That was the easier part: I carefully marked the spaces for new holes, got a hole puch (a nice tool to have for occations like this) and went ahead.

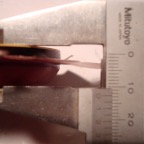

Another matter was that the coil former of the replacement diaphragm was larger in height. For minimum distortion, the voice coil's resting position should be in the very middle of the gap, so that excursion to either side results in the same level of change of magnetic flux. This is accomplished using different layers of gaskets to both sides of the diaphragm. I was lucky to have two drivers sitting on my bench, because to compensate for the increased height, I needed almost all gaskets from both of them.

Reassembling the driver and going through the alignment procedure, it turned out that the voice coil height wasn't quite right, so I had to go back and forth and exchange or insert gaskets of different thickness before I had everything in the right position. Getting there can be a pain, because you first insert the diaphragm with the top plate, then align it, then screw it tight, then add the metal mounting plate and tighten it's screws one by one - and any part of this process can alter distortion for better or worse, as even a small increase of the compression of the gaskets can make a difference to the voice coil's resting position.

Reassembling the driver and going through the alignment procedure, it turned out that the voice coil height wasn't quite right, so I had to go back and forth and exchange or insert gaskets of different thickness before I had everything in the right position. Getting there can be a pain, because you first insert the diaphragm with the top plate, then align it, then screw it tight, then add the metal mounting plate and tighten it's screws one by one - and any part of this process can alter distortion for better or worse, as even a small increase of the compression of the gaskets can make a difference to the voice coil's resting position.

This time, I managed to get it right, so that at loud volumes, there's but some mild distortion audible, which is typical (and, to some extent, even desirable) for this type of driver. So finally, I'm happy to have a functioning Jensen V21 in my Leslie!

PS. Regarding the Woofer

With all that said, changing my Rola C15L woofer to an original Jensen P15LL was really easy - and another sonic improvement. Again purchased second hand from the USA, directly upon insertion in my cabinet, it was performing nicely, blending with the V21 even better than the C15L, and delivering that classic "grunt" in the low end when pushing the level.

Next are some thoughts on different types of horn drivers and woofers used in tube amp based Leslies...

PS. Regarding the Woofer

With all that said, changing my Rola C15L woofer to an original Jensen P15LL was really easy - and another sonic improvement. Again purchased second hand from the USA, directly upon insertion in my cabinet, it was performing nicely, blending with the V21 even better than the C15L, and delivering that classic "grunt" in the low end when pushing the level.

Next are some thoughts on different types of horn drivers and woofers used in tube amp based Leslies...